Multi-munus compositum cladding pulveris

Descriptio

Nickel graphite composito puluis obductis est materia pulveris composita cum particulis graphitis ut core et metallo nickel sicut tunica exterior, quae bonam lubricationem et corrosionem resistentiam habet.Post scelerisque spargit, materia altum vires formare potest, oxidatio resistentia, scelerisque incursu resistentia et humilis friction coefficiens.

Specification

| Brand | Product Name | Chemia (wt%) | duritia | Temperature | Properties & Application | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | W | Mo | Cr | Al2O3 | MoS2 | WC | C | Fe | Ni | |||||

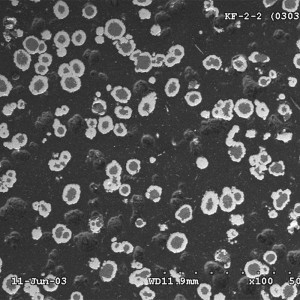

| KF-2 | NiAl82/18 | 20 | Bal. | HRC 20 | ≤ 800ºC | •Flamma, APS, Max.temperatura operativa 650°C. •Densa et machinabilis oxidatio resistens et obnitens induuntur. | ||||||||

| KF-6 | NiAl95/5 | 5 | Bal. | HRC 20 | ≤ 800ºC | •Flamma, APS, HVOF, Max.operating temperatus DCCC°C • Densa et machinis oxidatio resistens et conterentes repugnant efficiens | ||||||||

| KF-20 | Ni-MoS₂ | 22 | Bal. | HRC 20 | ≤ 500ºC | • Used pro mobilibus cione partium et molendibili cione annuli • Potest esse quod materia humilis friction | ||||||||

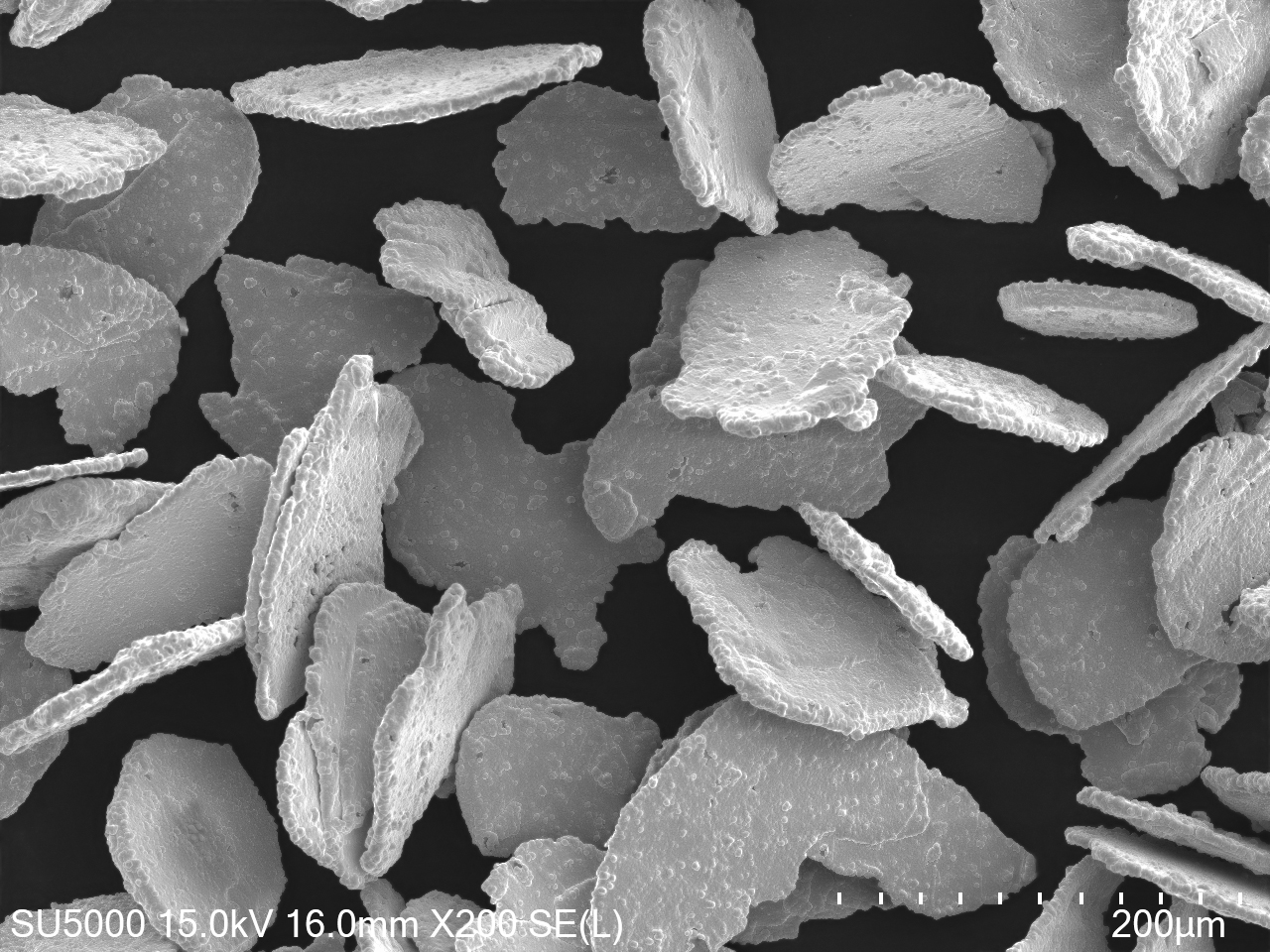

| KF-21T | Ni-Graphite 75/25 | 25 | Bal. | HRC 20 | ≤ 480ºC | •Flamma, Max.operating temperatus 480° F 1. Accinctus materias turbo compressor • Lorem ad nickel mixturae et ferro partes •Products with graphite content are apti ad titanium parts without edge . • High graphite content will accessing the lubrication performance • High nickel contentus erit amplio exesa resistentia • Similes producta sunt alia propter diversas OEM specifications | ||||||||

| KF-22T/R | Ni-Graphite 60/40 | 50 | Bal. | HRC 20 | ≤ 480ºC | |||||||||

| KF-21R | Ni-Graphite 75/25 | 25 | Bal. | HRC 20 | ≤ 480ºC | |||||||||

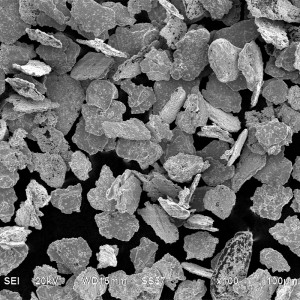

| KF-45 | Ni-Al2O3 77/23 | 23 | Bal. | HRC 40 | ≤ 800ºC | •Flamma, APS, irregularis • Potest adhiberi ad fuscinulam, terminalem superficiem et superficies signantes, ut stratum tutelarium formant | ||||||||

| KF-56 | Ni-WC 16/84 | Bal. | 12 | HRC 62 | ≤ 400ºC | •Flamma, APS, irregularis • Repugnantia ad percussio, exesa, abrasio et labens abrasio | ||||||||

| KF-50 | Ni-WC10/90 | Bal. | 10 | HRC 62 | ≤ 400ºC | •Flamma, irregularis • Repugnantia ad percussio, exesa, abrasio et labens abrasio | ||||||||

| KF-91Fe | Fe-WC | 4 | 27 | 9.5 | Bal. | 5.5 | HRC 40 | ≤ 550ºC | •Flamma, APS, irregularis, Max.temperatura operativa 815°C. • gere repugnant materiam membranae, quae adhiberi potest pro tristique fregit codex reparatione | |||||

| KF-110 | NiCr-Al 95/5 | 5 | 7.5 | Bal. | HRC 20 | ≤ 800ºC | •Flamma, APS, Max.temperatura operativa 980°C. • Plasma spargit sui compages | |||||||

| KF-113A | NiCrAl-CoY2O3 | Cr+Al:20, Ni+Co:75 | HRC 20 | ≤ 900ºC | •APS, HVOF, irregular, Max.temperatura operativa 980°C. • applicatur ad reparationem caliditatis compages iacuit vel vestium / improprie discursum partium | |||||||||

| KF-133 | NiMoAl | 5 | 5 | Bal. | HRC 20 | ≤ 650ºC | • Self compaging, common hard coating for supporting application • Lentus, cum bono corrosione resistentiae et effectus incussus • Usus machinae partes, sede et valvae portantes | |||||||

| KF-31 | Ni-Diatomite 75/25 | •Flamma, APS, irregularis, Max.temperatura operativa 650°C. • Pro sigillis stridibilis coatingis, partibus sigilli mobilibus inclusis, annulis sigillum terebile, materiae frictioni humile | ||||||||||||